|

Photovoltaic Technology

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Photovoltaic systems consist of arrays of modules (a module is the term for a number of interconnected cells packaged in a robust weather-resistant encapsulation), and balance of system components.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Version pdf | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Solar Cells

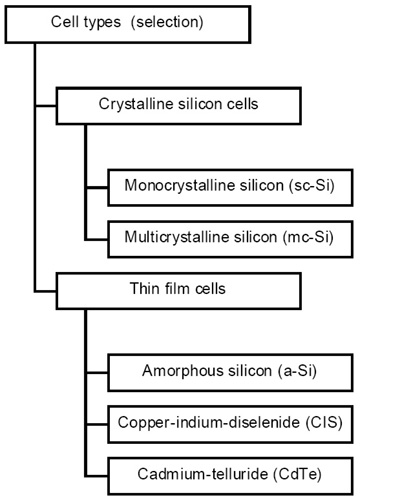

Various solar cells composed of various materials have been developed in the last decades. The vast majority of photovoltaic cells are made from silicon at present. Cells are typically classified as crystalline or thin film. Crystalline cells are sliced from ingots or castings or grown ribbons whereas thin film cells contain very thin layers on some low cost support material (most commonly on glass, stainless steel or plastic).

A solar cell consists of two or more layers of semi-conducting material, most commonly silicon. These layers of 0,001 up to 0,2 mm in thickness have different dotations (n- and p-dotations) and therefore different characteristics so that the resulting solar cell structure and function can be compared with a diode. When the silicon is exposed to light, electrical charges are generated and this can be conducted away by metal contacts as direct current (DC). The electrical output from a single cell is small, so multiple cells are electrically interconnected in series and parallel and encapsulated (usually behind glass) to form a module (sometimes referred to as a "panel").

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

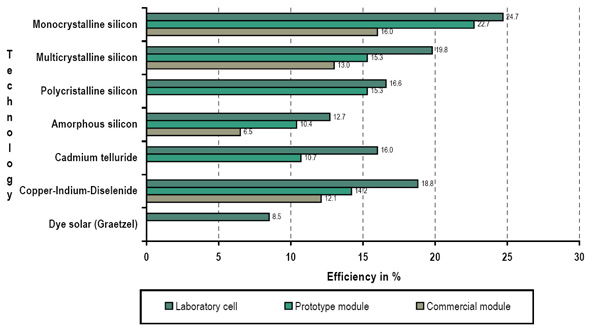

Figure 2: Solar cell and module efficiency of various technologies The efficiency rate of solar cells and modules depends on the technology (material) used. Different materials and combinations result in different efficiency rates. By combining materials with different spectral sensitivity and superposing several layers, cells can be more efficient. The theoretical maximum efficiency rate is around 42 % among the materials known and used for cells with one single layer. Higher rates can be obtained thanks to multiple junctions. The very top efficiency rates are shown for materials not listed in the figure above. These costly materials are used for concentrator systems and space applications. The efficiency rate is also a result of the corresponding state of the research & development process. Laboratory cells have the highest efficiency rates of up to 25 % and even more. They are usually small, individually produced and very expensive, hence not really representative of the technology. On the way to commercial modules, the cell production has to be industrialized and optimized according to the costs. The production process of modules implies furthermore connection of the cells, use of frames and cover as well as some more technical design. The efficiency rates of commercial modules are thus lower. By experience, one can say that the efficiency rate of marketable modules is some 30 % lower compared to laboratory cells (except amorphous silicon). Usually, it takes at least about 5 - 10 years from a laboratory cell to some marketable module.

Solar Modules Photovoltaic cells are interconnected and encapsulated between a transparent front, usually glass, and a backing material. Modules are normally rated between 50 and 200 Wp. The photovoltaic module is the principle building block of a photovoltaic system and any number of panels can be interconnected in series or in parallel to give the desired electrical output. This modular structure is a considerable advantage of the photovoltaic system, in many applications further modules can be added to an existing system as required. An overview over the most common solar module types shows that

Crystalline silicon based photovoltaic cells will stay dominant in the decade to come and considerable cost reductions will be available thanks to the newer thin film technology. Thin films require much less semiconductor material and less labor hence they are expected to be less expensive in production.

Table 1:

Overview over solar module types.

Balance of System The photovoltaic systems consist of modules and so-called Balance-of-system (BOS) components. Most important BOS components are:

Manufacturing and supply of these components have improved a lot in the last years and highly reliable gear is now available making the operation of photovoltaic systems very secure. Very much progress has also been made in manufacturing the mounting structure and above all in real building integration solutions. The costs for the BOS components have also been considerably reduced and count roughly for half of the photovoltaic system costs.

Photovoltaic Systems Photovoltaic systems can be divided into stand-alone and grid-connected photovoltaic systems.

Stand-alone systems

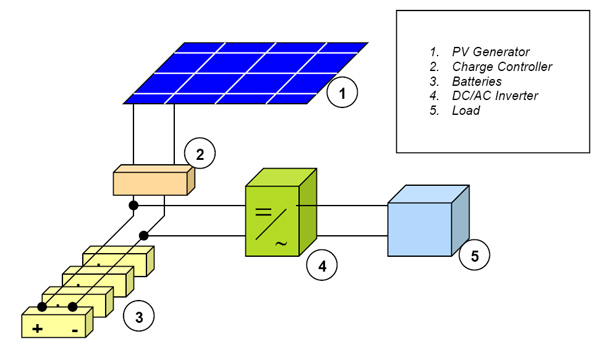

Stand-alone photovoltaic systems are used in areas that are not easily accessible or have no access to mains electricity but also where simple grid connection is less economic or not necessary for the application wanted. A stand-alone system is independent of the electricity grid, with the energy produced normally being stored in a battery. A typical stand-alone system would consist of a photovoltaic module or modules, a battery and charge controller. An inverter may also be included in the system to convert the direct current (DC) generated by the photovoltaic modules to the alternating current form (AC) required by normal appliances. Stand-alone systems can be subdivided in professional applications (telecommunication, water pumping, street furniture, illumination, etc.) and rural domestic applications (isolated housing).

Grid-connected Systems

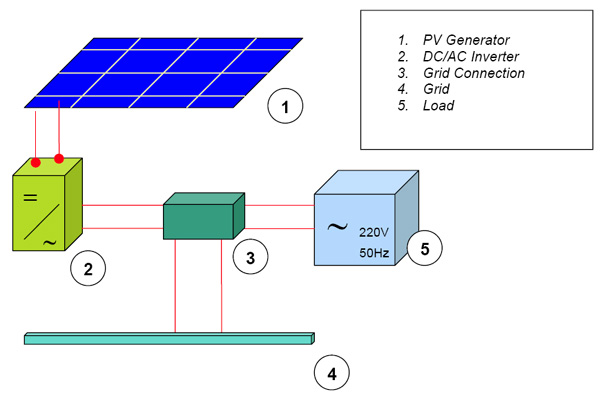

Photovoltaic systems can also be connected to the local electricity network. The electricity generated by the photovoltaic system can either be used immediately (e.g. for systems installed on offices and other commercial buildings), or can be sold to one of the electricity supply companies. Power can be bought back from the network when the solar system is unable to provide the electricity required (e.g. at night). This way, the grid is acting as a kind of “energy storage system” for the photovoltaic system owner, which means that a battery storage for the photovoltaic system is not needed. Grid-connected systems can be subdivided into photovoltaic power stations (centralised on-grid installations on large scale with corresponding land use) and building integrated photovoltaic applications (distributed on-grid installations without any additional land use).

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||